CNC Machining Capabilities

| Service | Cookies | Description |

|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |

| Service | Cookies | Description | |

|---|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |

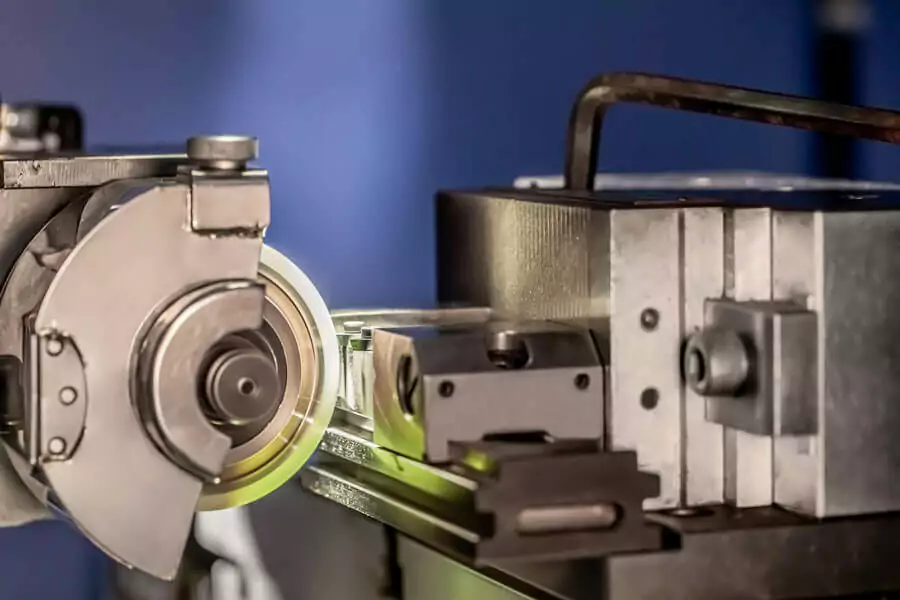

JC Machining is a key provider of high-performance grinding services for applications with critical tolerances and surface finishes. Originally working specifically in the Tool and Die industry, we have extensive experience in Form and Surface Grinding.

Today JC Machining grinds custom parts for a wide variety of industries such as aerospace, automotive, electronics, medical, optoelectronics, and injection mold and die.

We perform highly specialized, small cylindrical grinding operations, diameters from 0.2mm to 20mm, with very tight tolerances, very fine surface finish requirements, and complex shapes and forms.

Our facility is equipped with top-of-the-line CNC precision grinding machines – Click below to view our list.

Common grinding applications include finishing intricate joints and precision-machined parts with critical surface finishes and geometric tolerances. From designing and prototyping custom components to executing CNC ground precision finishes, we are dedicated to providing exceptional consistency and quality control in line with the most recent ISO 9001:2015 standards.

Surface finishing refines the texture (lay, roughness, and waviness) of machined parts, enhancing functionality, durability, and aesthetics when applied properly. Our expert CNC Precision Grinding engineers recognize the critical role of flawless surface finishes, particularly in aerospace and medical applications. The following list highlights common finishes provided by our team for CNC ground parts.

As-machined parts are components that come directly from the machine. This finish is suitable for those prioritizing dimensional integrity over aesthetics. Precision CNC grinding is for components needing strict geometric tolerances and high-quality surface finishes. Surface roughness finishes typically range from 1.6 μm Ra to as low as 0.8 μm Ra.

1.6 μm Ra – Recommended for stressed parts and tight fits, this Ra rating is adequate for surfaces bearing light loads and slow-moving components.

0.8 μm Ra – Regarded as high-grade, this surface finish demands precise control during production. It is essential for parts subject to stress concentration, intense vibration, and fast rotation.

Fine polishing can be applied to CNC ground parts with high surface finish requirements. A surface roughness of Ra0.008μm can be achieved with our polishing processes.

JC Machining also has many years of experience in tool and die molds which often require this method. Please contact us for more information about this.h

Typically used on CNC Turned or CNC machined aluminum anodizing offers numerous benefits for components, including enhanced corrosion resistance, increased wear resistance, improved aesthetics through color options, optimized heat dissipation, and a stronger surface for long-lasting durability.

JC Machining offers various levels of anodized coatings from basic to hard anodizing based on your component finishing requirements.

Black oxide finishing delivers several advantages for components, such as corrosion protection, reduced light reflection, improved aesthetics with a sleek black appearance, enhanced lubrication properties, and minimal dimensional changes.Unlike painting or plating surface treatments, black oxide will not chip or flake.

We can provide a variety of sandblasted finishes to meet customers surface finishing requirements.

JC Machining is well experienced with sandblasting of medical instruments, automotive parts, and electronic device components that require precise measurements and impeccably smooth surfaces.

In our current facilities, we have:

Other advanced manufacturing equipment.

There is no MOQ. We offer solutions such as one-off rapid prototypes, custom low-volume CNC machining, and mass production with short lead times.

Even though our in-house machines can machine larger parts, we recommend these sizes:

Lead times will vary depending on your project complexity and our capacity:

For larger projects, in general, you can expect shipment 2-3 weeks after sending in your confirmed order.

With rapid one-off CNC prototypes, global delivery can be within 10 days.

Our sales office operates from 8:00 am to 6:00 pm local time (GMT+8)

Our factory operates 24/7 Monday to Sunday.

As Machined, Polishing, Sand Blasted, Black Oxide, TiN, TiCN, TiALN, AlCrN, DLC and Chrome Plated.

We offer free ground shipping limited to customers in Taiwan and China. For other locations, our sales and fulfillment team will work with the carriers of your choice.

We understand that your 3D data and designs are invaluable to your business. Therefore, we take the protection of your intellectual property rights (IPR) very seriously. We encrypt all files that are transferred using SSL, ensuring that they can’t be intercepted while being uploaded to our servers.All the information and any files which you upload onto our platform are stored securely, and only ever shared within our organization with those employees who need access to it in order to manufacture your parts.

We ensure confidentiality across the entirety of your order; original drawings are not shared with 3rd party suppliers as all our production is done in-house.If you would like some additional reassurance, we can sign a Non-Disclosure Agreement.

JC Machining has a CNC manufacturing team of professional engineers and machinists to reduce manufacturing redundancy, optimize CNC programming, shorten machining time, improve surface finish, and deliver the best quality machined parts.We take each project personally and carefully examine each drawing, we can then enhance the 2D/3D designs by adding clarity and detailed information and further analyze your design to accommodate any special fixturing and machining strategies used to produce your parts at a very reasonable cost.

Our manufacturing team follows strict quality control standards, delivering 100% accuracy at strict tolerances. You can also call or email us at any time, and we’ll help with ordering parts, design feedback, material recommendations, and answer any questions.

If you’re looking for enhanced capabilities like tighter tolerances, more complexity, or high-volume production quantities JC Machining in-house manufacturing deliver the solutions you need.

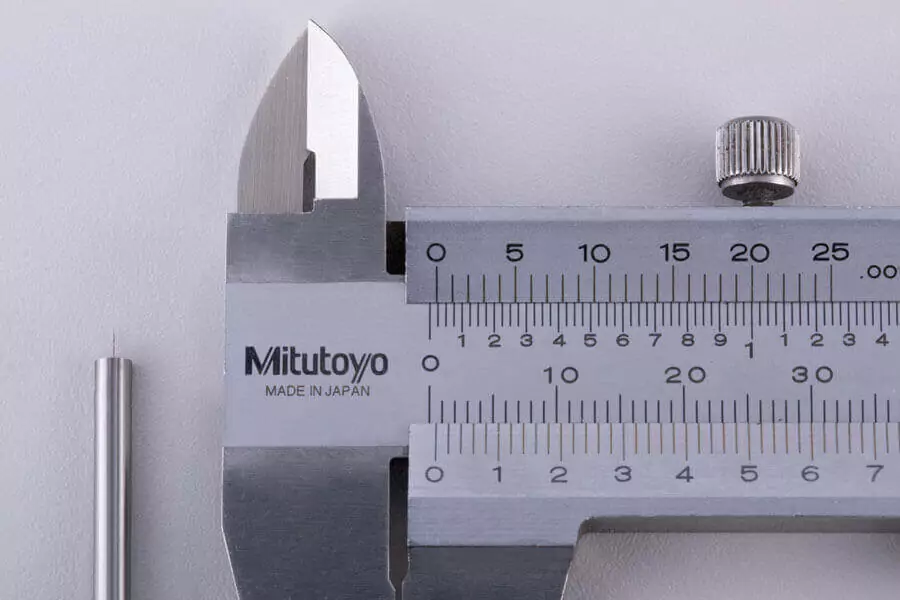

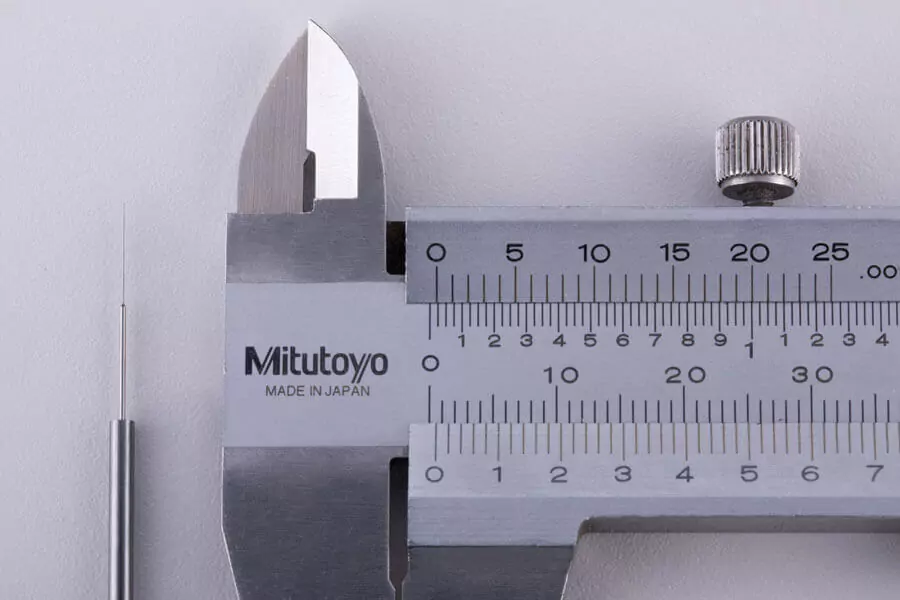

| Needle pin | |

| Material Used: | Carbide or ASP60 |

| Machining Process: | NP5 precision grinding |

| Finish: | As machined |

| Tolerance: | +/-0.008 |

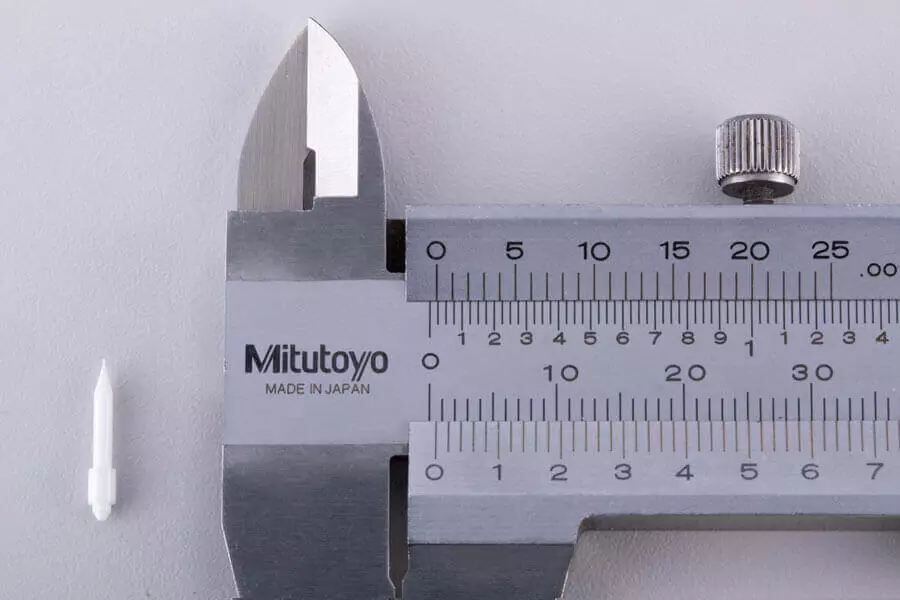

| Dispensing pin (semiconductor) | |

| Material Used: | ceramics |

| Machining Process: | EWAG grinding |

| Finish: | As machined |

| Tolerance: | +/-0.01 |

| Carbide needle pin | |

| Material Used: | Carbide |

| Machining Process: | NP5 grinding |

| Finish: | As machined |

| Tolerance: | +/-0.002 |

| Inserts (optical electronic parts) | |

| Material Used: | SKD11, ASP23, ASP60, SKD61 |

| Machining Process: | NP5 precision grinding, surface grinding, |

| Finish: | As machined, TIN coating, TiCN Coating |

| Tolerance: | +/-0.002 |

| Plastic mold core | |

| Material Used: | DC53 |

| Machining Process: | Central grinding, surface grinding, |

| Finish: | As machined |

| Tolerance: | +/-0.008 |

| Hot runner nozzle 100 mm | |

| Material Used: | FDAC+SKD61+beryllium copper |

| Machining Process: | CNC turning+central grinding |

| Finish: | As machined |

| Tolerance: | +/-0.02 |

| Hot runner nozzle 250 mm | |

| Material Used: | FDAC+SKD61+beryllium copper |

| Machining Process: | CNC turning+central grinding |

| Finish: | As machined |

| Tolerance: | +/-0.025 |

| Plastic mold core | |

| Material Used: | DC53 |

| Machining Process: | Central grinding, surface grinding, |

| Finish: | As machined |

| Tolerance: | +/-0.005 |