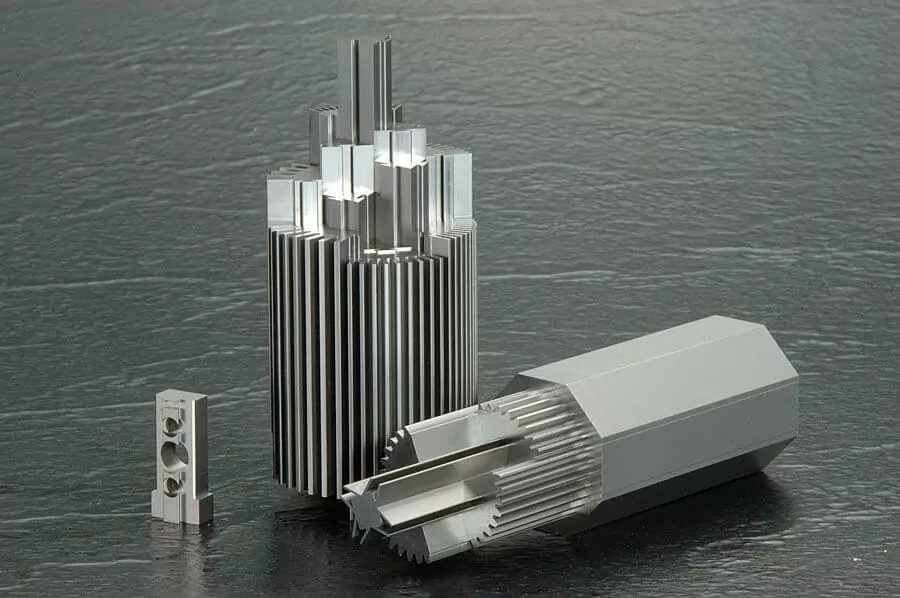

CNC Machining Capabilities

| Service | Cookies | Description |

|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |

| Service | Cookies | Description | |

|---|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |

We have decades of expertise in custom press stamping mold components. As both a manufacturer and distributor, we offer excellent service and top-quality mold components machining services for press tooling.

We are experts in the machining of press die components. Our team has the skills and equipment necessary to produce high-quality mold components that meet your exact specifications, even for the most complex and intricate designs.

Whether you need custom sizes, geometry, or material types, we can accommodate your needs. We specialize in machining mold Components for press dies that are suitable for a range of operations, including trimming, forming, coining, and bending.

At JC Machining, we understand the importance of maintaining tight tolerances in order to meet the precise requirements of our clients for mold parts machining. To ensure the highest level of accuracy, we use specialized equipment and top-of-the-line CNC lathe turning machines to produce custom press punch components with precision.

Our team of skilled machinists has the knowledge and experience to provide the best solutions and deliver high-quality outcomes at competitive prices with short lead times. Trust us to handle all of your custom punch component needs with exceptional results.

Send drawings in 2D or 3D files with Dimensions & Specs

Select the manufacturing Qty, process, materials, finishes, & certifications you require.

Our engineers will thouroughly analyse your design, and you will receive our manufacturing quote.

Once your order is confirmed we will start production and keep you informed with regular status updates.

In our current facilities, we have:

Other advanced manufacturing equipment.

There is no MOQ. We offer solutions such as one-off rapid prototypes, custom low-volume CNC machining, and mass production with short lead times.

Even though our in-house machines can machine larger parts, we recommend these sizes:

Lead times will vary depending on your project complexity and our capacity:

For larger projects, in general, you can expect shipment 2-3 weeks after sending in your confirmed order.

With rapid one-off CNC prototypes, global delivery can be within 10 days.

Our sales office operates from 8:00 am to 6:00 pm local time (GMT+8)

Our factory operates 24/7 Monday to Sunday.

As Machined, Polishing, Sand Blasted, Black Oxide, TiN, TiCN, TiALN, AlCrN, DLC and Chrome Plated.

We offer free ground shipping limited to customers in Taiwan and China. For other locations, our sales and fulfillment team will work with the carriers of your choice.

We understand that your 3D data and designs are invaluable to your business. Therefore, we take the protection of your intellectual property rights (IPR) very seriously. We encrypt all files that are transferred using SSL, ensuring that they can’t be intercepted while being uploaded to our servers.All the information and any files which you upload onto our platform are stored securely, and only ever shared within our organization with those employees who need access to it in order to manufacture your parts.

We ensure confidentiality across the entirety of your order; original drawings are not shared with 3rd party suppliers as all our production is done in-house.If you would like some additional reassurance, we can sign a Non-Disclosure Agreement.

JC Machining has a CNC manufacturing team of professional engineers and machinists to reduce manufacturing redundancy, optimize CNC programming, shorten machining time, improve surface finish, and deliver the best quality machined parts.We take each project personally and carefully examine each drawing, we can then enhance the 2D/3D designs by adding clarity and detailed information and further analyze your design to accommodate any special fixturing and machining strategies used to produce your parts at a very reasonable cost.

Our manufacturing team follows strict quality control standards, delivering 100% accuracy at strict tolerances. You can also call or email us at any time, and we’ll help with ordering parts, design feedback, material recommendations, and answer any questions.

| Stamping Dies | |

| Material Used: | ASP23 |

| Machining Process: | Wire cutting |

| Finish: | TIN coating |

| Tolerance: | +/-0.01 |

| Stamping Dies | |

| Material Used: | SKD11 |

| Machining Process: | Wire cutting |

| Finish: | As machined |

| Tolerance: | +/-0.01 |

| Forming punch | |

| Material Used: | SKD11 |

| Machining Process: | Profile grinding |

| Finish: | As machined |

| Tolerance: | +/-0.005 |

| Forming punch | |

| Material Used: | SKD11 |

| Machining Process: | Profile grinding |

| Finish: | As machined |

| Tolerance: | +/-0.005 |

| Forming punch | |

| Material Used: | SKD11 |

| Machining Process: | Profile grinding |

| Finish: | As machined |

| Tolerance: | +/-0.005 |

| Stamping punch | |

| Material Used: | ASP23 |

| Machining Process: | Profile grinding and EDM |

| Finish: | As machined |

| Tolerance: | +/- 0.01 |

| Stamping punch | |

| Material Used: | SKH51 |

| Machining Process: | Profile grinding |

| Finish: | As machined |

| Tolerance: | +/-0.002 |

| Press Mold Components | |

| Material Used: | SKH51, SKH9, SKD61, SKD11, ASP23, ASP60, |

| Machining Process: | Profile grinding, Cylindrical Grinding, Surface Grinding, NP5 |

| Finish: | As machined |

| Tolerance: | +/-0.01 |

| Inserts (optical electronic parts) | |

| Material Used: | SKD11, ASP23, ASP60, SKD61 |

| Machining Process: | NP5 precision grinding, surface grinding, |

| Finish: | As machined, TIN coating, TiCN Coating |

| Tolerance: | +/-0.002 |