We know it can be challenging to order CNC machining, so we make it as straightforward as possible for our customers to access our Taiwan CNC machining service. In this article we will walk you through everything you need to know to order your prototypes or small batch production from us.

Table of Contents

First contact

We make it as simple as possible to order Taiwan CNC Machining Services from us. You can start by contacting one of our engineers online or by phone to discuss your project. You can upload your own 2D or 3D design (CAD) file to our online portal or send us samples or drawings to work from.

What standard CAD file types can I upload to your online portal?

- STEP

- STP

- SLDPRT

- DXF

- STL

- IPT

- 3DXML

- PRT

- SAT

Clarifying your needs

The next step is for us to work with you to understand your requirements and clarify your needs. We will ask you some questions about your project. You don’t need to be an expert to work with us and get a quotation for our Taiwan CNC Machining Services, but it helps if you can provide us with the following details:

- Manufacturing material

- Quantity required

- Tolerance specifications

- Heat treatment processes

- Required hardness

- Surface coating or finish

Can I get a quote from a sample component or drawing?

You don’t need to have a CAD file ready to upload. We are also completely happy to work from your 2D or 3D design files, physical drawings and sample prototypes. You can scan a pdf file to email to us, or send us a physical sample that you want us to duplicate. We will then measure and reverse-engineer it in-house for you. The entire process is managed in-house to ensure confidentiality and accuracy.

How soon will I receive my finished product?

Our standard turnaround time is 3 weeks, from initial consultation to shipping. Some Taiwan CNC Machining Services may offer a more rapid turnaround, but we are open and clear with our customers and offer guaranteed delivery times. In reality, we ship most projects globally within 10 days. When you discuss your specific project with us, our sales representative can give you a very accurate and realistic timing estimate based on the quantity and difficulty of the project.

Production Solutions

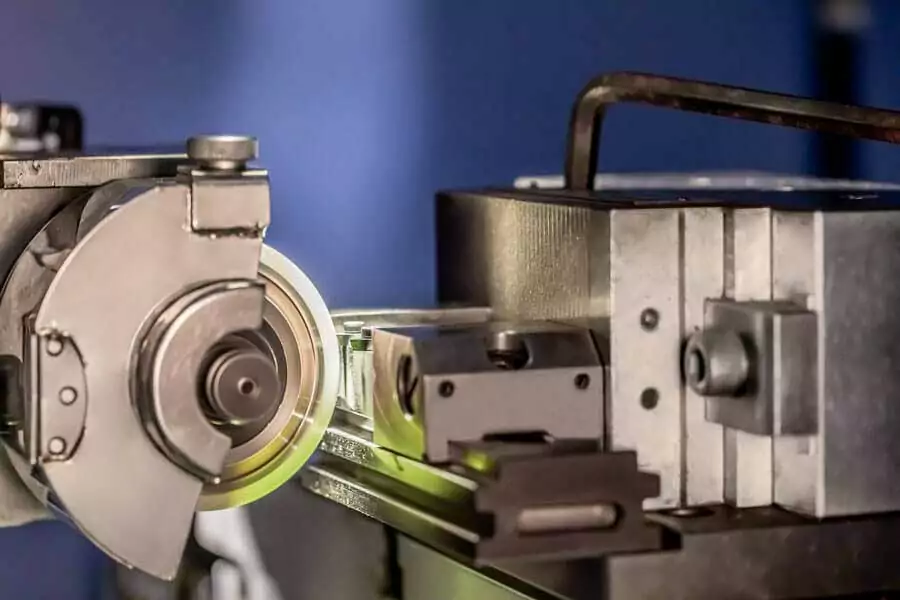

We offer a comprehensive Taiwan CNC Machining Service, including wire and sink EDM machining and all types of grinding as well as high quality CNC turning and milling services. As part of our production solutions we offer many options for surface coatings and finishes depending on the intended use of the finished product.

What Taiwan CNC Machining Services do JC Machining Offer?

While working out the ideal production solution for your project, we will identify the ways we can minimize time and costs to achieve the optimum results. We apply our 30 years of experience as a Taiwan CNC Machining Service supplier to get you the best possible results at very competitive prices.

Our experienced team of engineers, flexible production methods and extensive equipment inventory enable us to offer faster manufacturing and shorter lead times to our customers without compromising on quality or service levels.

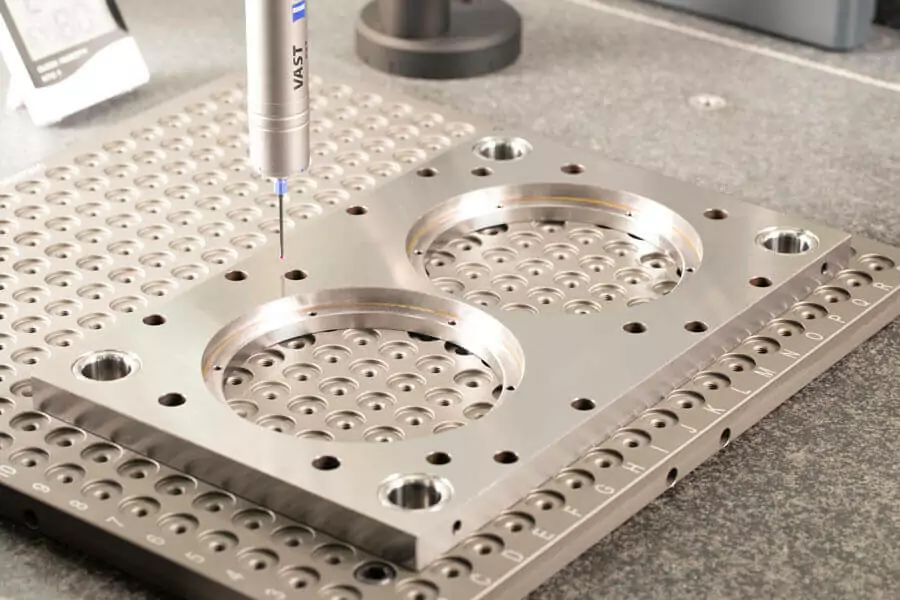

Quality control and inspection

Our superb quality control is why we can offer our zero-defect guarantee, and is the reason our Taiwan CNC Machining Services are in demand by die makers, mold manufacturers, tooling manufacturers, and our worldwide clients from the aerospace, medical and automotive industries. If you can turn it, mill it, or grind it, JC Machining can make it!

JC Machining Quality Control

- ISO 9001:2015 Certification

- High precision CNC machining services up to 2µm (0.0001″) tolerances

- ISO-2768-m and ISO-2768-c standards for tight tolerances

- Automatic & Manual Quality Control Systems

- 3D Coordinate Measuring Machine (CMM)

- Zero defect guarantee

Quality control is to internationally recognized standards, and includes very accurate automated 3D coordinate measurement as well as visual and manual inspections and measurements by our expert staff to ensure tolerances are met. If you have specific quality requirements we will be entirely happy to add them to our quality control measures for your project.

After sales support

JC Machining offers a one-stop, customer-focused Taiwan CNC Machining Service to our global customers. It doesn’t matter how complex your design, or how many you need. We offer prototyping as well as mass production from our state-of-the-art, fully equipped, CNC machining center in New Taipei, Taiwan.

Our personalized client management team supports you all the way from first contact through product shipping to after sales service and repeat business options. Our customer support will follow up on your project to ensure that you are completely satisfied, and will be ready to offer the same excellent service for your next project.

Why choose us for your Taiwan CNC Machining Service?

There are many reasons why we think you should choose JC Machining for your Taiwan CNC Machining Services, not least is our zero defect guarantee! But we have many other strengths that you might want to consider before making a decision.

How safe is my intellectual property?

When looking for a Taiwan CNC Machining Service, ask if all the work will be carried out in-house. We are a one-stop manufacturing center, so you know that your designs stay with us through the entire production cycle with nothing going off-site. There’s no risk of intellectual property being leaked by outsourcing, and our confidence in the security of our systems makes us more than happy to sign non-disclosure agreements with our clients.

Will I get good customer service?

Will you get a quick response to your queries, from someone who knows you and understands your project? We have six technical sales representatives and six sales assistants to answer customer questions and respond to any issues that you may have. Your drawings and in-progress work are tracked across our multiple departments by barcodes so your representatives can have immediate updates on progress without delays.

What are the key benefits of our Taiwan CNC Machining Service?

- In-house, one-stop manufacturing

- Total confidentiality

- Quick response to customer questions

- Expert point of contact for your project

- Barcode tracking of projects for rapid progress reporting

- Quick turnaround time

- Zero defect guarantee

- Superb ISO certified quality control

Our technical sales team are always ready to assist you in working out the details for your project and answering questions on material, process and finishing choices, so don’t worry if you are unsure or undecided. Contact our friendly technical sales team and discover the benefits of 30 years of expertise in Taiwan CNC Machining Services from JC Machining.