Advances in design and manufacturing of injection molds has driven current demand for the injection molding of ever more intricate and complex designs. JC Machining is fully equipped to deliver the precision CNC machining required to be successful in today’s competitive injection molding markets.

Table of Contents

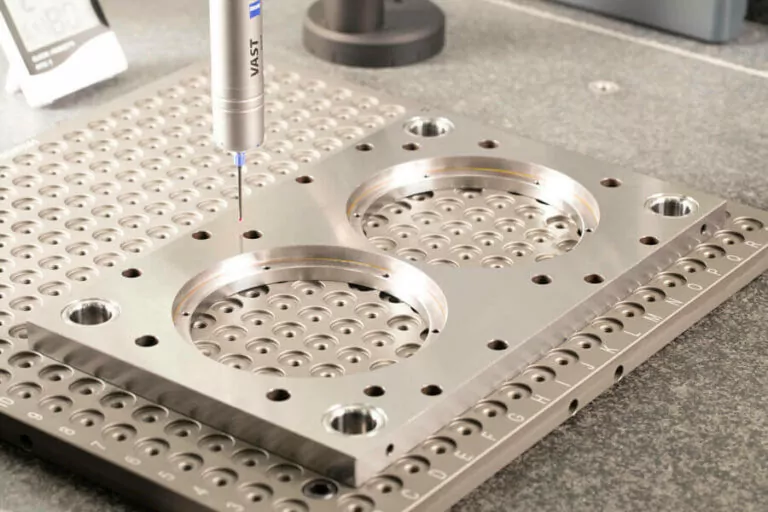

Injection mold manufacturers today specify very tight tolerances and complex shapes that can only be achieved by excellent CNC machining services. JC Machining quality control uses coordinate measurement machines (CMM) as shown above to maintain our zero defect manufacturing guarantee by ensuring tolerances are met.

Is injection molding a growth industry in 2024?

The injection molding industry has a projected compounded annual growth rate (CAGR) of 4.8% to 2030. Steady growth in injection molding is being driven by mass production of complex plastic shapes and innovative use of new materials including bioplastics and metals.

Why is injection molding the best mass production method?

- Design consistency

- Complex shapes

- Low cost per unit

The factors that make injection molding a successful growth industry are strongly affected by the use of CNC machining services to manufacture injection molds. CNC machining has made it possible to rapidly create extremely accurate molds that enable low cost, consistent molding of complex and intricate parts on an ever increasing scale.

What are the significant issues for injection mold manufacturing?

Injection molds are becoming more complex to meet market demands for manufacturing of intricate parts, and volumes of injection molded products are increasing. The combination of complexity and need for higher production volumes to balance competitive margins leaves no room for errors in injection mold manufacturing processes. This is why CNC machining services are now the preferred providers of injection mold and injection mold component manufacturing solutions worldwide.

Why is JC Machining your perfect CNC machining service provider for injection mold manufacturing?

JC Machining offers mold design and the full range of CNC machining services and expertise to manufacture any injection mold entirely in-house without outsourcing of any components. We manufacture not only the mold itself, but also inserts, tooling, flow components and sensors required for state-of-the-art injection molding to the highest modern standards.

Complete injection mold manufacturing solutions from JC Machining

The flow diagram above shows the process from initial inquiry to delivery of your finished product. We work with you to build a shared understanding of your exact requirements and contribute our expertise to refine and develop the perfect solution to meet your needs.

What are the 7 key stages of our injection mold manufacturing process?

- Material, accuracy and cost specification

- Mold design from 2D or 3D drawings

- CNC rough machining

- CNC fine machining of cavity and core

- Cavity & core polishing, EDM & grinding

- Mold testing, refinements and corrections

- Quality checking and shipping

Our capabilities are supported by our enviable portfolio of advanced CNC machines, operated by our team of highly experienced technicians. Our comprehensive tooling and skilled workforce enable us to provide CNC machining services in the six categories required for successful injection mold manufacturing:

- Die Sink & Wire EDM Machining

- Optical Profile Grinding

- Tungsten Carbide Grinding

- CNC Turning

- CNC Milling

- CNC Grinding

The highest quality injection mold manufacturing requires expertise in EDM machining, optical profile grinding and tungsten carbide grinding to achieve the finishes and accuracy required. Our Japanese EWAG Universal Tooling Grinders, Rollomatic NP5, and WAIDA CNC grinding machines are essential tools in this process. Our Seibu and Agie Charmilles EDM machines deliver pinpoint accuracy for the most demanding projects.

Talk to one of our engineers, upload a 2D or 3D design (CAD) file to our online portal or send us samples or drawings. You will discover the best results you can get from any CNC machining service, delivered to you worldwide at highly competitive prices.