When precision and accurate reproduction of designs are of the utmost importance, CNC turning services are the preferred choice of product designers and manufacturers for rapid prototyping and serial production. CNC turning services provide an efficient and convenient manufacturing process that reduces time to market, minimizes risk, and enables you to focus on your core competencies.

Table of Contents

What are CNC Turning Services?

CNC turning services use subtractive manufacturing to remove material from a rotating workpiece and create a desired shape. CNC turning services offer a versatile process that is used to manufacture a wide variety of parts, including shafts, cylinders, tubes, and gears.

CNC turning services are the most efficient option for rapidly machining shapes that have an axis of symmetry. This is not limited to rods and other entirely cylindrical objects, although turning rods, pins, punches, and bars between centers is perhaps the single fastest CNC operation apart from drilling. Offsetting a workpiece in a rotating chuck enables very precise CNC turning of cams and lobes.

What are the benefits of employing CNC turning services?

Commercial CNC turning services like JC Machining have comprehensive, high quality, in-house CNC machinery that is not cost-effective for small businesses to own themselves. This makes commercial CNC turning services the obvious way to manufacture very high quality parts and prototypes without having to make significant capital investments in purchasing or upgrading existing equipment.

There are three features that make CNC turning services attractive for both prototyping your designs and production manufacturing.

- Precision machining

- Exact reproduction of designs in any volume

- Rapid production time

The accuracy of CNC turning for manufacturing parts to precise tolerances rapidly and to exactly specified designs makes CNC turning services the preferred choice for prototyping. The speed of cutting combined with the ease of producing multiple parts to the exact same design and tolerances makes CNC turning just as good for volume production.

Why do businesses use CNC Turning Services for prototyping and manufacturing?

Specialist CNC turning services are very good at optimizing and manufacturing parts rapidly to very high quality inspection standards. This enables you to receive your finished products more rapidly and speeds the process from design to market, keeping you competitive.

There are also economies of scale from providing comprehensive CNC turning and machining services, which often results in a lower cost per part than you might expect, and almost certainly a lower cost per part than can be achieved by a small business without specialized expertise and equipment.

For a CNC turning service provider like JC Machining, CNC turning, milling and grinding are the core competencies of our business. Outsourcing your CNC turning needs to us enables you to benefit from our expertise while maintaining your focus on the core competencies of your own business, which maximizes value and minimizes risk.

Is CNC turning really cost effective for mass production?

CNC turning can be very cost-effective for CNC manufacturing of high volume components. This is because a professional CNC turning service can be automated with expert quality control and production management to ensure excellent results. This is why at JC Machining we are able to offer a zero defect guarantee to our customers.

In mass production using CNC turning services, both accuracy and production speed can be set to the needs of a customer by running multiple machines simultaneously with the same programming to manufacture identical parts.

What are common applications of CNC Turning Services?

CNC turning services are suitable for the manufacturing of symmetrical components and sections of larger workpieces that have an axis of symmetry that means they can be turned between two centers or clamped in a rotating chuck. The example above is a PCB drilling machine component turned from copper. Almost any material can be machined using CNC turning services.

In the automotive industry, CNC turning is used to manufacture high strength components including crankshafts and axles in harder materials. The aerospace industry relies on CNC turning to produce critically important aircraft components including control rods, landing gear, and engine components.

What can you make with CNC turning services?

- Hardened, long-life stamping tools

- Gears, bearings, spindles, shafts & pins

- Precision cutting tools & punches

- Machining of very hard tooling and components including instruments & surgical tools

- Specialized cutting tools, holders, & arbors

- Aerospace engine parts & other precision machined components

- Micro-mechanical & micro-electromechanical components

- Electronic & semiconductor components

- Automotive engineering parts including engine and transmission components

As well as specific automotive and aerospace applications, CNC turning is used to cut both soft and hard metals for a wide range of general products that are used across different industries. Milling and turning are very common CNC machining services, and these two operations can manufacture almost any complex shape.

What are the benefits of JC Machining CNC turning services?

JC Machining is a Taiwan-based provider of CNC turning services. Our CNC machining services include CNC turning, milling, and grinding with special expertise in hardened materials and the application of a wide range of finishes. We manufactured the cutting die in the image above in SKD11 hardened steel with an AlCrN coating.

Our state of the art CNC turning machines are extremely accurate. Our Mazak Nexus CNC turning machines feature a cutting accuracy of 0.01mm, and we also use the industry leading Mazak Quick Turn 200, with advanced Mazak Smooth control technology.

8 Reasons To Choose JC Machining For CNC Turning Services

- Zero-Defect Manufacturing Guarantee

- Automatic & Manual Quality Control Systems

- Rapid Quotes with Guaranteed IP Confidentiality

- ISO 9001:2015 Certification

- ISO-2768-m and ISO-2768-c Standards for Tight Tolerances

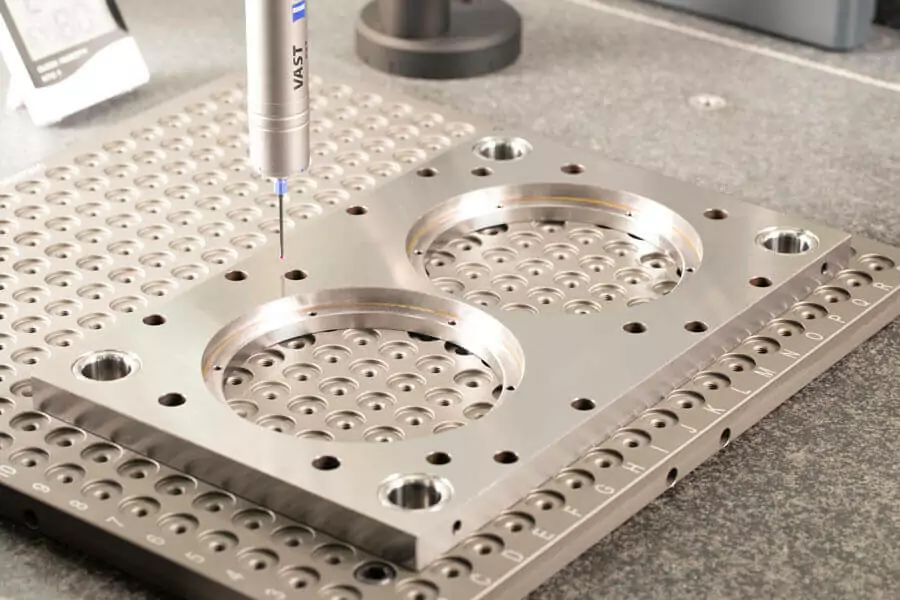

- 3D Coordinate Measuring Machine (CMM)

- Tolerances to 0.01mm

- Many Finishing Options

Using JC machining CNC turning services could not be easier. Upload your design to our website in CAD format and we will respond with a rapid quotation. Our expert technicians will review your design for possible optimization options and discuss this with you if they find efficiency gains that do not compromise the quality of the product. We ship anywhere in the world at very competitive rates.

Because JC Machining is dedicated to supplying high quality, affordable, CNC manufacturing services to our global customers, we offer a complete range of CNC machining, turning, and grinding services. Our services include CNC milling, grinding, wire and sink EDM. Contact us to discuss how we can manufacture your designs to the highest quality standards with zero defects guaranteed.