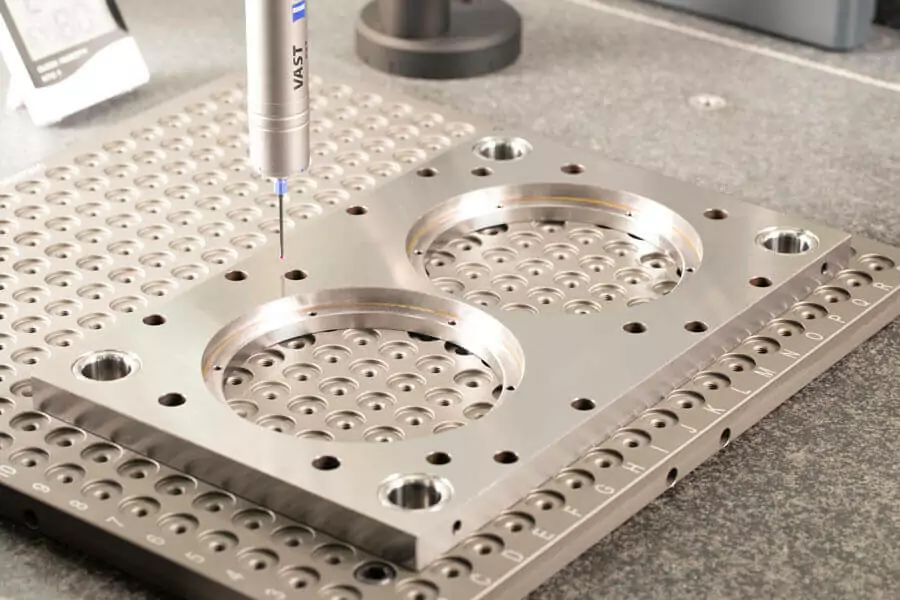

Injection mold component manufacturing relies on superior CNC machining services to supply complex components with the precision required for accurate and efficient molding and release. JC Machining guarantees the tight tolerances required to achieve consistent, high quality results.

Table of Contents

Why are injection mold components manufactured by CNC machining services?

CNC machining is the only way to achieve the tight dimensions and tolerances required to manufacture high quality injection molding components like the photoelectric mold parts shown above. These parts require precision cylindrical grinding, and machining using the full range of CNC machining services.

To achieve consistent, reliable results in the injection molding process, all injection molding components must be machined extremely precisely. It is not practical to achieve the accuracy required for today’s complex designs without using modern CNC machines.

What components are needed to make an injection mold?

Injection molding has become a very sophisticated technology since it was invented in the 19th Century, with significant breakthroughs in plastic materials in the 1940s and the invention of hollow molding in the 1970s. Today’s molds have multiple components and parts that must fit together perfectly and be machined accurately to compensate for the pressure and thermal expansion of the molding process.

- Mold cavity

- Mold cores

- Mold plates

- Ejector pins

- Gate & runner systems

- Mold inserts

- Molding tools

- Sensors & controls

Injection molds are assembled from many parts, starting with the CNC machining of the mold cavity and mold cores. The mold is held together by mold plates that keep all components aligned, and ejector pins assist in releasing the mold after each injection molding cycle.

The mold cavity creates the shape of the completed part, while mold cores are machined and positioned in the mold cavity to make spaces within the product, including threaded holes for assembly. Inserts can be machined to become part of the finished product. Sensors and flow control components optimize the molding and release processes.

How are CNC machining services used for injection mold component manufacturing?

Component manufacturing for injection molding uses the same wide range of CNC machining services used for mold cavity and core machining processes, including CNC milling, wire and sink EDM and surface grinding to cut intricate shapes and create specific surface finishes.

- CNC Grinding

- Tungsten Carbide Grinding

- CNC Turning & CNC Milling

- Die Sink & Wire EDM Machining

- Optical Profile Grinding

Taiwan CNC Machining Services For Injection Molding Components

JC Machining has a full complement of CNC machines in-house specifically designed for producing injection mold components. Our equipment list includes Japanese EWAG Universal Tooling Grinders, the Rollomatic NP5, and WAIDA CNC grinding machines.

Expert CNC Machining Services From JC Machining

- In-house manufacturing without outsourcing

- Confidential service

- Rapid response to your questions

- Your personal expert point of contact

- Barcode tracking for swift reporting of project progress

- Quick turnaround from initial contact to finished product

- ISO certified quality control & zero defect guarantee

Our state of the art CNC machines enable us to manufacture custom injection mold tooling with high precision and accuracy, achieving strict tolerances of 0.002mm for ID/OD, concentricity, roundness and cylindricity, parallelism and verticality. We guarantee zero defect results for all our clients.

Quality control and inspection

Our quality control meets or exceeds international certification standards, and includes both manual and automated inspection and measurement by our expert staff to ensure all tolerances and standards are met.

- CNC machining services to 2µm (0.0001″) tolerances

- ISO-2768-m and ISO-2768-c for tight tolerances

- Manual & Automated Quality Control

- 3D Coordinate Measuring Machine

- ISO 9001:2015 Certification

- Zero defect guarantee

Contact one of our engineers online or by phone to discuss your project. You can upload your 2D or 3D design (CAD) file to our online portal or send us samples or drawings to work from. With 30 years of experience in Taiwan CNC Machining Services, JC Machining will deliver the best results at very competitive prices, delivered to your door worldwide.