A vast number of modern products, ranging from smartphones to advanced aircraft, owe their existence to the dependable and adaptable nature of CNC milling services. CNC milling is perfectly suited for both rapid prototyping and mass production in materials like plastic and metal. In this article we consider the impressive benefits and uses of CNC milling services in the world today.

Table of Contents

People have been turning symmetrical objects on lathes and achieving high precision results for centuries, but the multi-axis CNC milling machine is a relatively new invention, which is unbeatable for subtractive machining, giving CNC milling services the capability to make square shapes, bevels, slots, angles, and complex cures, and even the milling of round or near-spherical objects.

How is CNC milling different from CNC turning?

In CNC milling operations, the workpiece is clamped in a stationary position and the cutting tool, which is mounted on a rotating spindle, is moved to make cuts in the workpiece. The workpiece is usually mounted in a horizontal (X-Y coordinate) machine vise, and the spindle, fitted with any of a range of cutting tools designed for specific cutting operations, is moved by computer control along X, Y, and Z axes.

A CNC milling machine often has a set of tools mounted on a turret that can be rapidly swapped over to make different types of cut without significantly slowing down the cutting process. In common with all types of metal machining and cutting operations, however, CNC milling employs a special cutting fluid to keep the cutting tool and workpiece cool as well as to clear chips and debris from the surface of the workpiece to improve the finish and extend tool life.

As CNC machining operations, the accuracy of CNC turning and CNC milling are both extremely high, and tolerances of 0.01mm or better are easily achievable with our modern, high quality, CNC milling machines. Our CNC milling machines include the highly sophisticated Makino V33i Vertical 3-Axis Hard Milling Machine, which is designed to mill dies and molds from hardened materials with extreme precision.

What are CNC milling services used for?

CNC Mills can be used simply to drill holes, but they are best suited for the milling of parts that are asymmetric, often with complex shapes. Asymmetric components cannot easily be manufactured by CNC Turning without repositioning the stock repeatedly in the chuck, if it is possible to turn them on a lathe at all. This makes CNC milling services invaluable for precision machining of prototypes as well as accurate batch production of parts that require fine tolerances and perfect duplication.

What can you make with CNC milling services?

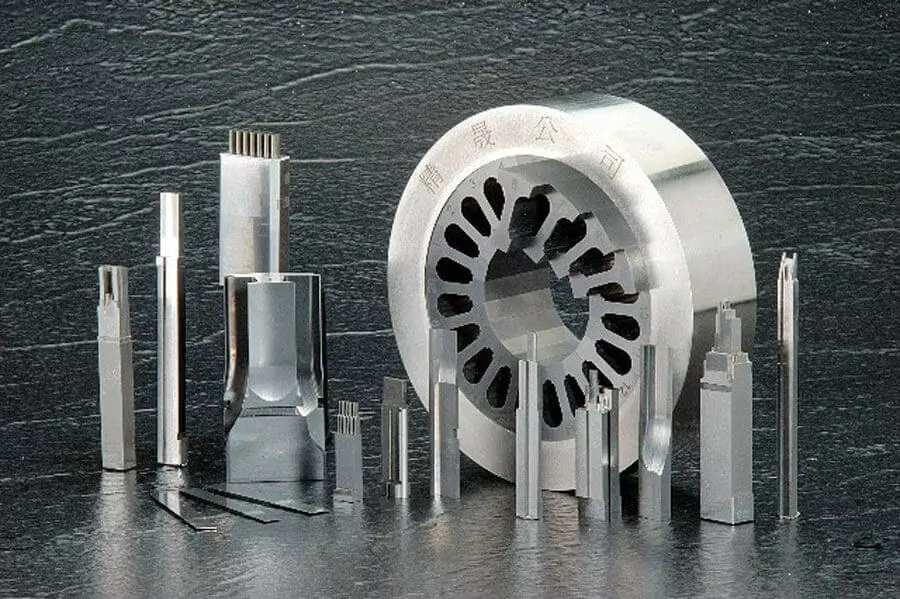

- Precision dies & stamping tools in hardened materials

- High precision injection molds & mold parts including fine surface textures

- Intricate, complex molds for metal casting

- Precision dies & punches, including non-round, oblong & form punches

- High pressure, hardened extrusion dies

- Machining of very hard tooling and components including instruments & surgical tools

- Specialized cutting tools, holders, arbors & fixtures

- Precision machined components including aerospace turbine blades

- Micro-mechanical & micro-electromechanical components

- Electronic & semiconductor components

- Automotive engineering parts including engine and transmission components

It would be possible to carry out these operations using simpler machines, but even the process of repositioning and reclamping the stock for a sequence of different cutting tasks is likely to cause registration errors and distortion of the finished product. Milling and turning are the most common CNC machining services, and between these two operations almost any complex shape can be manufactured.

The more axes of independent motion that the CNC milling machine can use, the more complex the shapes it can cut, and the less likely it will be that the workpiece may need to be moved to a different machine or repositioned in the vise for any specific cutting process. The most sophisticated CNC milling machines offer multiple axes of motion for very high accuracy and precision.

What are the benefits of JC Machining CNC milling services?

The benefits of our CNC milling services become clear when you are making combinations of chamfers, grooves, profiles and square face cuts that require very high precision on a single workpiece. Carrying out all these tasks in a single machine, and only having to clamp the workpiece in position once, increases accuracy and speeds up the overall cutting time. Our state of the art CNC milling machines are multi-axis models, which minimizes the need for repositioning the workpiece and maximizes accuracy.

10 Features of JC Machining CNC Milling Services

- 3,4,5 Axis Milling

- Tolerances to 0.01mm

- Many Finishing Options

- Rapid Quotes

- IP Confidentiality Guaranteed

- Zero-Defect Manufacturing

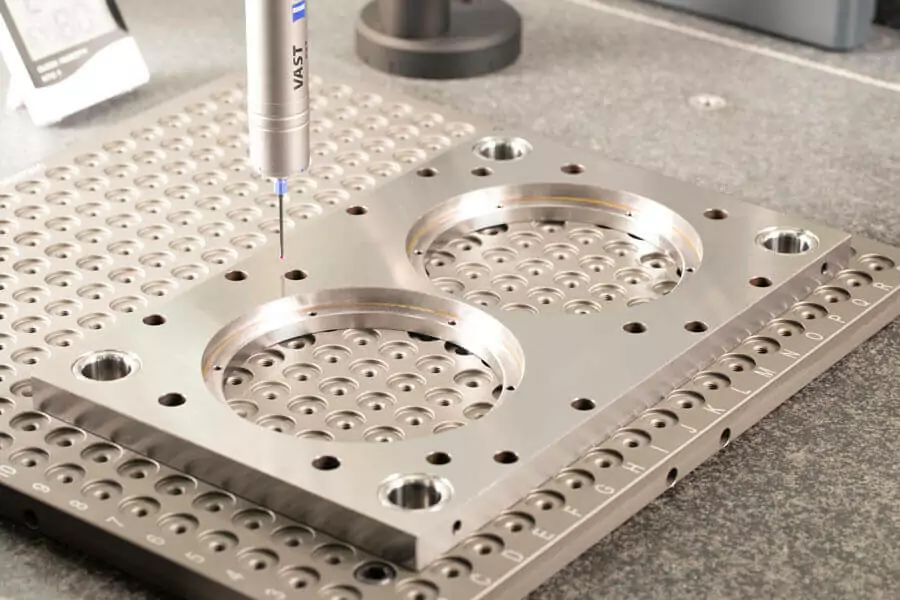

- Automatic & Manual Quality Control Systems

- ISO 9001:2015 Certification

- ISO-2768-m and ISO-2768-c Standards for Tight Tolerances

- 3D Coordinate Measuring Machine (CMM)

An advantage of using JC machining CNC milling services is the ease and convenience of being able to simply upload your design to our website in CAD format and receive rapid feedback. This includes cost quotations as well as suggestions from our expert technicians if they can see a way to optimize your design. We then mill your design and ship it to you anywhere in the world at very competitive rates.

At JC Machining, we are dedicated to delivering the highest quality CNC milling services to our global customers at affordable prices. Not only experts in CNC milling, we are a one-stop-shop for all CNC machining and grinding services. Contact us today to discover how we can manufacture your designs with zero defects guaranteed and industry leading accuracy.